Is your labelling scale PEAL compliant?

Does your scale have the ability to print in bold to highlight allergens?

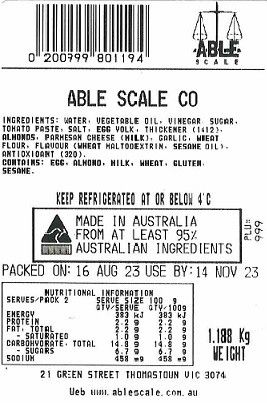

PEAL is a new Food Standard requirement aimed at making allergen information on food labelling clear and consistent. If you have, labelling scales and print food ingredients then this new standard may apply to you. Food labelling provides essential product information to consumers. PEAL labels promote regulatory compliance and a clearer communication between the customer and the manufacturer; as such, PEAL has now been widely used across a range of industries.

Plain English Allergen Labelling (PEAL)

What is PEAL?

Plain English Allergen Labelling is part of the new allergen labelling laws that have been introduced by Food Standards Australia and New Zealand (FSANZ), in the interest of flagging any and all foods that may trigger severe allergic reactions. Going above and beyond basic labelling, PEAL encompasses all product details, environmental impact, usage instructions, and any other necessary warnings. Such practices help streamline operations for businesses while simultaneously playing a vital role in promoting transparency, traceability, and consumer confidence. This approach helps consumers to make informed decisions, fostering a sense of trust between the customers and the manufacturers. PEAL labelling also contributes to sustainable practices by promoting responsible consumption and waste reduction.

Why has PEAL been introduced?

PEAL has been introduced to address the growing consumer demand for transparency, ethical practices, and sustainability in the products they purchase. In an age where consumers are more conscious of the environmental and social impact of their choices, PEAL labelling helps bridge the gap between what manufacturers provide and what consumers want to know. Food allergies can have serious and potentially life-threatening consequences. As a food service provider, it is your responsibility to offer secure and enjoyable dining experiences to your patrons. One of the fundamental approaches to achieving this goal is by acquiring knowledge about food allergies.

What is the deadline for compliance with PEAL?

25 February 2024 is the final deadline for PEAL compliance.

Does your business need to comply with PEAL?

If you are printing ingredients on labels for food, it is highly likely that you will be required to ensure that your operation is PEAL compliant, though this ultimately depends on the products you manufacture or sell, the industry you operate within, and the regulations of your specific region. It is highly recommended that you research the regulations and guidelines relevant to your industry and region before taking any food products to market. Even if PEAL protocol is not an immediate requirement within your jurisdiction, you may wish to consider adopting it anyway, as PEAL labels demonstrate transparency and respect for the customer.

Technological Features of Label Scales

If you are currently using scales to print labels with food information, then your current set of scales will need to comply with PEAL requirements. Depending on the make and model of your weighing scales, you may be able to utilise a programming service to make your current set of scales PEAL compliant. Failing this though, you may find that you will have to purchase a new set of scales to ensure PEAL compliance.

Besides label printing, modern, premium labelling scales feature a range of technological features, some of which may include:

Data Storage: A capability to store product and label data for quick retrieval.

Connectivity: A device that provides options for connecting to networks, databases, or other systems.

High Precision Load Cells: Scales that use advanced load cell technology ensures precise and reliable weight measurements.

Dual Display: Scales that show both weight and pricing information on separate displays enhances clarity.

Touchscreen Interface: An intuitive touchscreen interface that streamlines operation and reduces errors.

Multiple Units of Measurement: Scales that offer varying measuring units (kg, g, lb, etc.).

Auto-Label Printing: An automatic labelling function that is determined by the weight of the item, which can save you time in the long run (and in the short run too).

Database Integration: Scales that can connect to databases will enable easy access to product information and pricing.

Checkweighing Function: A checkweighing feature that alerts operators when a product falls outside preset weight ranges.

Overload Protection: This features safeguards against damaging the scale by indicating when weight capacity is exceeded.

Barcode Scanning: Integration with barcode scanners to speed up data entry and improve accuracy.

How to Choose the Right Labelling Scale?

When selecting the right labelling scale for you and your business, there are numerous aspects to consider, though the relevance of each will ultimately be determined by the specific needs and requirements of your business. That said, some common factors to keep in mind might be:

Weighing Accuracy: Perhaps the most obvious factor, but nonetheless, probably the most integral. It’s always highly important to choose a label printing scale with high precision to ensure accurate measurements.

Label Printing Capability: An equally obvious if important aspect to look for in labelling scales is the machine’s ability to print labels deftly and reliably with all necessary information.

User-Friendly Interface: Always look for easy-to-use controls and displays to minimise human error.

Label Customisation: It’s good to opt for a scale that allows you to design and customise labels to your specific needs.

Compliance: Always ensure your labelling scales comply with PEAL, and any other regulations or legal requirements that are relevant to your industry and region.

Check weighing Function: If needed, choose a scale with a check weighing feature so to monitor products against set weight limits.

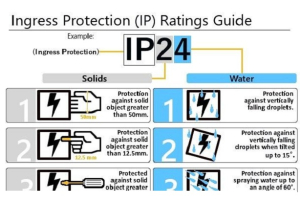

Durability: Always look for a strong construction that withstand heavy weights, frequent use, and the demands of a high-pressure business environment.

Maintenance: It’s smart to consider scales with minimal maintenance requirements for efficiency.

Warranty and Support: Always check the manufacturer's warranty and the availability of customer support.

The Ishida Uni3, Ishida Uni5 and the Avery XTi are all excellent choices of labelling scales for consumers as well as businesses.

Conclusion

Ultimately, PEAL provides benefits for both consumers and businesses alike, and by integrating label scales, businesses can ensure regulatory compliance, accurate and transparent labelling, and customer trust. You can check out the extensive range of Able Scale labelling scales here. Here at Able Scale, we take immense pride in our industry acumen, unwavering customer service, and our ability to present an extensive selection of products to cater to the distinctive requirements of business proprietors. If you’re interested in browsing the full range of Able Scales products, you can start with the Able Scales homepage here. We’re here to help, so if you need assistance with anything, don’t hesitate to contact Able Scales directly here, and one of our friendly staff members will help you find what you’re looking for.

Have questions about our products and services?

We are here to help. Please fill in our online enquiry form below, and we will respond to you within the next business day.

Call us Today

Call us Today