A Comprehensive Guide to Choosing High Capacity Balance Scales in the Laboratory Weighing Industry

Are you on the hunt for a reliable set of laboratory balances? Able Scale has an extensive range of high quality precision balances that are as affordable as they are dependable. Read on to learn more…

What is a High Capacity Balance?

A high capacity balance (also commonly referred to as a “precision balance” or simply a “laboratory balance”), is a type of weighing instrument used to measure larger quantities of materials with higher weight capacities compared to analytical balances. While analytical balances are designed for measuring small mass with very high precision, typically to four decimal places, high capacity balances are designed for weighing larger quantities with slightly lower precision, typically to two decimal places.

The chief difference between an analytical balance and a precision balance is the readability. Analytical Balances have a higher readability, typically measuring up to 0.0001g, whereas precision balances have a lower readability of around 0.001g. Consequently, Analytical Balances are generally more costly due to their increased precision.

If you really want to understand the distinction between precision and accuracy; precision refers to the level of agreement or consistency between individual measured values. It is a measure of how many decimal places are present in a given measurement, indicating the level of detail or granularity - precision is indeed important because it reflects the degree of variability or spread among the measured values. Accuracy, on the other hand, pertains to the proximity of a measured value to the true or accepted value; it signifies how well the measurement reflects the actual quantity being measured. Accuracy is also significant as it indicates the correctness or trueness of the measurement. Both are important when it comes to analysing data.

Who Uses High Capacity Precision Balances?

High Capacity Precision Balances have various applications across a high number of different industries. Here are just some common areas where these balances are utilised on a daily basis…

- Pharmaceuticals: High Capacity Precision Balances are extensively used in the development and manufacturing of drugs and medicines across the pharmaceutical industry. These balances ensure accurate weighing of active pharmaceutical ingredients, excipients, and other raw materials, ensuring that precise formulation and adherence to strict quality control standards are strictly followed.

For example - Ohaus Explorer Semi Micro analytical balances - Education: High Capacity Precision Balances play a crucial role in educational institutions, particularly in science laboratories. They are used to teach students about measurement techniques, experimental procedures, and the principles of accuracy and precision. These balances provide students with hands-on experience in weighing and reinforce scientific theories through practical experiments.

- The Food & Beverage Industries: The food and beverage sectors have long relied on accurate and precise measurements for quality control, compliance with hygiene standards, and meeting regulatory requirements. High Capacity Precision Balances are utilised in this industry to weigh ingredients, additives, spices, and other components during recipe formulation, production, and quality assurance processes.

- Industrial Weighing: High Capacity Precision Balances are employed in various industrial sectors for weighing purposes. They ensure compliance with regulations, accurate measurement of raw materials, and precise monitoring of product quantities. Industries such as manufacturing, logistics, and quality control rely on these balances to maintain precise inventory control, optimise raw material usage, and ensure compliance with weight-based regulations.

The Best Tips on Choosing the Right High Capacity Balance Scales

When choosing the right high capacity balance scales for you, there are several factors to consider. Here are some tips to help you make an informed decision…

Application:

Consider the specific application or purpose for which you will be using the balance. Different industries and laboratories have varying requirements. Determine whether you need the balance for pharmaceutical research, industrial weighing, food testing, or any other specific application. This will help you choose a balance with the necessary features and functionalities for your needs.

Scale Capacity:

It is advisable to select a scale that is appropriately sized to meet your weighing requirements without unnecessary excess capacity. If you need to weigh items with varying weights, consider the weight range of the lightest and heaviest items and choose a scale with a capacity that accommodates that range effectively.

Scale Readability:

Readability refers to the smallest weight increment that a scale can accurately measure. A higher readability indicates a smaller increment and greater accuracy of the scale. The readability can vary, ranging from 0.1 gram to 0.0000001 gram, depending on the scale. Therefore, it is recommended to choose a scale with a high readability to ensure consistently precise and accurate measurements.

Display Readability:

The other kind of readability is just as important - especially if you’re not looking to make a long day longer! The readability of the display plays a significant role in user experience and productivity. We suggest you opt for a balance with a clear and easily readable digital display that provides accurate and legible information, even under varying lighting conditions. Consider that different individuals have different eyesight capabilities, and some employees may require larger or brighter text on the display for better visibility and ease of use.

FAQs

What are some standard features of high capacity balances?

High capacity balances typically include features such as large weighing capacity, high readability, taring functionality, and built-in (or external) calibration. Most modern models will also feature a user-friendly touchscreen/keypad interface for easy operation and adjustment of settings.

What is the 'accuracy' in a laboratory balance?

Accuracy in a laboratory balance refers to how close the measured value is to the true or accepted value. It reflects the correctness or trueness of the measurement. Accurate balances provide measurements that are close to the actual value, with minimal systematic or random errors. The accuracy of a balance is typically indicated by the balance's specifications and may be influenced by factors such as calibration, environmental conditions, and the quality of the balance itself.

Are there accessories that can be used to enhance the functionality of your laboratory balance scale?

Indeed there are! There are several accessories available to enhance the functionality of laboratory balance scales, such as anti-vibration platforms, draft shields, calibration weights, printer or data output devices, and software integration.

How often should lab balances be calibrated?

The frequency of calibration for lab balances depends on various factors, including the balance's usage, manufacturer's recommendations, and regulatory requirements. As a general guideline, it is recommended to calibrate lab balances at regular intervals, such as once every six months or annually. However, more frequent calibration may be necessary for balances that undergo heavy use or are subject to demanding environmental conditions. It's important to consult the manufacturer's guidelines and consider any specific industry or regulatory standards applicable to your laboratory.

What are the sources of error in laboratory balances?

Various factors can contribute to errors in laboratory balances, such as improper (read: irregular) calibration, environmental factors such air currents and humidity, operator mishandling (i.e., human error), or, quite simply, mechanical issues (i.e., problems with the balance's internal components, which can sometimes be put down to the machine ageing).

The Best Laboratory Balance Scales Available on Able Scale

The Ohaus Explorer Precision has up to four user-programmable touchless sensors so as to minimise cross contamination and mitigate the wear and tear that’s normally associated with repeated touching of the balance. All Explorers come with newly optimised linearity and repeatability specifications and enhanced vibration filtering to provide better balance stability, and all models come standard with AutoCal automatic internal calibration.

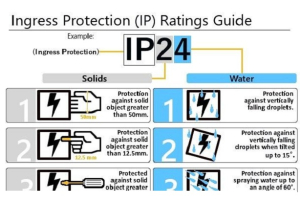

The A&D GX-M is dust and waterproof, and can withstand water projected from any direction. It also features impact shock detection, tare memory, automatic self-calibration, and more.

The A&D GP Series incorporates an enhanced weighing sensor and a Double Leveraged Super Hybrid Sensor (SHS) to bring you a state of the art internal calibration that stands to save you both time and money. The motor-driven internal calibration mass is equivalent to a 50kg calibration mass in terms of top loading capacity on the weighing pan. This series also offers Automatic Self Calibration and One Touch Automatic Calibration.

You can scope out the Able Scale’s full range of state of the art precision balances here.

Able Scale is a family owned and operated business that offers quality products to a team of personnel with over 100 years combined experience of providing our customers with the best possible solutions to suit their businesses. You can check out our full range of stock here, or contact us directly here.

Have questions about our products and services?

We are here to help. Please fill in our online enquiry form below, and we will respond to you within the next business day.

Call us Today

Call us Today