Counting scales play an integral part across a vast number sectors. In almost every industry, the necessity for small parts is resounding. These tiny components play crucial roles in the production of plastic products, electronic devices, automotive parts, and even in less expected sectors like food processing and pharmaceuticals. As such, a common hurdle for manufacturers across countless fields is the need to accurately count a vast array of small parts. Due to the tedious nature and the impracticality of manual counting in an industrial environment, which often leads to human error, more efficient strategies must be employed. That’s where precision counting scales come in. High quality precision counting scales — such as High Resolution Counting Scale - A&D FC-i & FC-Si Series — eliminates the need for individual counts, thereby saving time and money while enhancing the precision of the inventory counts. Read on to learn how counting scales can revolutionise your business.

Small Parts Counting Scale: Understanding the Basics

Counting scales offer a significant advantage when it comes to both time management and inventory control. Manual counting is a challenging method that’s time-intensive and rife with human error. The investment in a counting scale quickly pays off, particularly during inventory checks, thanks to the direct cost reductions from saved labour and increased accuracy.

Counting scales come in various capacities and precision levels, enabling the selection of the most suitable model for precise counts. To count small parts, place a known quantity on the scale to determine the average weight, then weigh the bulk quantity for an accurate count based on this average. The scale correctly calculates the number of pieces in the load by dividing its total weight by the individual piece weight. Following this, you can use the counting scale to quickly weigh and count an entire batch. Counting scales offer you savings in both time and money.

Small Parts Counting Scale Accuracy

Ensuring precise inventory control is key to optimising the supply chain, which forms the backbone of a company. Counting scales provide a practical solution for businesses of all sizes to accurately manage inventories of small parts and components.

The precision of scale counting is influenced by several factors, including:

- Weight Consistency: Ensuring each part's weight is uniform is crucial, as variations can lead to inaccuracies in the final count.

- Number of Parts Being Tallied: The total amount of parts being counted can impact precision; larger quantities may introduce greater potential for error.

- Calibration Process: A thorough calibration ensures the scale accurately reflects the average weight of individual parts, vital for reliable counting.

- Measurement Error: Involves inaccuracies in scale readings due to the resolution, which is the smallest weight difference the scale can detect.

- Bias: Refers to a consistent deviation in the scale readings from the true value, which can skew counts.

- Scale Variability: Denotes the inconsistency in scale performance over time or across different conditions, affecting counting accuracy.

Accurate inventory management prevents the risk of lost sales due to shortages and avoids the immobilisation of essential capital through excess stock. A manufacturer without a balanced inventory risks halting production and failing to meet delivery deadlines. By keeping precise track of current inventory and understanding its turnover rate, businesses can forecast their requirements more accurately and manage operational costs effectively.

Adjusting Counting Scales for Small Parts

If you wish to adjust your counting scales to small parts, you will typically want to follow these steps:

Setting the Scale to Zero / Taring

Before counting begins, it's essential to "tare" the scale, effectively setting its reading to zero. This step ensures that the weight of any container or tray used is not included in the final measurement. Simply place the container on the scale and press the tare button, which zeroes the display, readying the scale for item counting.

Weighing a Sample

To accurately count your items, start by weighing a representative sample. The size of this sample can vary but should align with the scale's capacity and your accuracy needs. A larger sample size generally yields more precise counts.

Inputting Item Data

A critical stage in the process is inputting data about the item into the scale’s system, including its individual weight. This can be done manually or automatically via barcode scanners or RFID readers, depending on your scale model.

Calculating the Count

With item data and sample weight entered, the scale calculates the total number of items using this formula:

Number of items = Total weight / Weight of a single item

For example, a sample weighing 500 grams, with each item weighing 5 grams, indicates a total of 100 items.

Counting Additional Items

After establishing the sample count, add the remaining items to the scale for a comprehensive count, using the previously mentioned method to determine the total quantity.

Verification

For quality assurance, occasionally verify the scale's counts manually. Regular accuracy checks of the counting scale are recommended to identify any discrepancies, which could suggest issues with the initial sample weigh-in, data entry, or a need for recalibration. Addressing any discrepancies promptly ensures consistent count accuracy.

Counting Scales Accuracy Errors

Errors in counting scales, especially when dealing with large numbers of parts, can arise from several factors:

- Size Inconsistencies: Inconsistencies in part sizes, or the absence of a standardised counting procedure.

- Human Error: Human error is another significant contributor to weighing errors, as manual data entry mistakes or incorrect sample handling can lead to inaccuracies. Errors in determining the sample size or the average piece weight can also significantly affect the final count, making it crucial to select an appropriate and representative sample.

- Environmental Factors: Environmental factors can also play a major role in scale errors; variations in temperature, humidity, or the presence of vibrations can interfere with the scale's accuracy. To mitigate these errors, you and your personnel can implement a systematic approach to the scale counting, ensuring careful calibration and environmental control.

How Does Sampling Work on a Counting Scale?

Counting scales streamline the task of tallying large numbers of identical items. You can ensure precise counts by considering the following steps:

- Sample Counting: You can start by manually counting a specific number of items to create a sample. Common sample sizes include 10, 20, 50, or 100 items, which are then placed on the scale.

- Determine Average Weight: The scale calculates the total weight of the sample and divides this by the sample's item count to find the average weight per item. For instance, if the total weight of 10 items is 50 grams, the average weight per item is calculated as 5 grams.

- Bulk Counting: For counting larger quantities of the same item, the scale utilises the previously established average weight to approximate the total item count. For example, placing items weighing a total of 500 grams would, based on the 5 grams average weight, result in an estimated count of 100 items. The scale computes the total item count by dividing the bulk's total weight by the average weight per item, ascertained from the sample.

- Tare Function: To exclude the weight of a container, use the scale's tare function. This involves setting the empty container on the scale, pressing the tare button to zero the scale, and then adding the items. The scale will then display the weight of the items only.

- Re-Sampling: Should there be a potential variation in item weights (e.g., screws from different production batches), re-sampling may be necessary for each new batch to ensure accuracy.

Differences Between Internal Resolution and Displayed Resolution

| Feature | Resolution / Displayed Resolution | Internal Resolution |

| Definition | The smallest weight difference a scale can visibly indicate, also known as readability. | The precision level at which a scale can subdivide its maximum capacity, reflecting its ability to convert physical weight into digital signals. |

| Example | If a scale's readability is 0.1g, it won't display the weight of an item weighing 0.0052g. | The scale's capacity is divided by the minimum detectable part weight, crucial for accurate counting and measuring. |

| Main Function | Indicates the minimum weight increment displayable to the user. | Determines the accuracy of the scale's readings, especially for small measurements. |

| Capacity Relationship | Calculated as the ratio of the scale's maximum weight capacity to its readability. | Often defined by a stability-enhancing ratio between internal and displayed resolution, such as 1:1, 4:1, or 10:1. |

| Stability Influence | Affects how users perceive and interpret weight measurements on the display. | Crucial for the scale's measurement accuracy and stability, can be influenced by external factors like temperature. |

| Application | Vital across all contexts for accurate weight reading. | Especially important in settings requiring high precision, such as scientific research and industrial applications. |

Where Are Counting Scales Used?

Counting scales have proven to be indispensable tools across a wide number of industries, including:

- Inventory Management: Counting scales significantly speed up the process of tallying inventory items, minimising manual effort and decreasing the likelihood of errors, thereby ensuring precise inventory tracking.

- Production & Manufacturing: Within assembly lines or manufacturing processes, counting scales guarantee that the appropriate quantity of components is used in each product. Additionally, they're employed to tally parts prior to packaging or dispatch.

- Packaging and Shipping: By counting incoming merchandise, and confirming the accurate count of packaged or shipped items, counting scales play a vital role in packaging and shipping.

- Retail: For retail businesses, counting scales aid in effectively managing stock levels, counting cash, or any other scenario that demands quick and exact counting

Counting Inventory Manually vs. Counting Scales

Counting scales are crucial for efficiently managing inventory, transforming tedious manual counts into quick, accurate stock assessments. Manual inventory tracking is not only time-consuming but also prone to errors due to the monotony of the task. In contrast, counting scales expedite the process by converting weight into count data, making them ideal for handling large volumes of small items in warehouses, factories, and other industrial settings. Counting scales function by weighing a sample and calculating the total count based on the weight of individual units, with their effectiveness depending on both the scale's readability and its internal resolution—the latter determining its precision in converting weight measurements into digital output. Selecting a scale with the appropriate readability and high internal resolution is essential for ensuring accurate inventory counts.

Types of Counting Scales

- Bench Scales: Bench scales are extremely common across a number of industries, owing to their great adaptability. They are perfect for measuring small to medium-sized objects, providing the versatility required in numerous manufacturing environments.

- Floor Scales: Built to handle bigger and heavier loads, floor scales are a staple in sectors such as logistics and shipping. They play a critical role in counting and verifying large volumes of merchandise.

- Portable Counting Scales: Designed for mobility, portable counting scales are lightweight and easy to transport, ideal for conducting inventory checks and on-site assessments. Their portability makes them invaluable for tallying items across various locations.

Counting Scales: Features & Considerations

When selecting your counting scales, you may wish to ensure that the model your considering comes equipped with the following features:

- Tare Functionality: The tare functionality allows users to subtract the weight of a container, displaying only the net weight of the contents.

- Memory Function: Certain counting scales have the capability to retain information for various items, simplifying the process of switching between different items for counting purposes. This feature proves particularly beneficial in the manufacturing and packaging sectors, where there is a frequent need to count a varied range and high number of items.

- Accumulation Mode: This function enables the counting of items across various batches, aggregating the overall total. Accumulating counts proves advantageous in both packaging and shipping processes.

- Multiple or Single Display: Certain counting scales feature a single display, whereas others boast multiple displays, with different screens presenting different data points. Users who prefer visual confirmation of sample weight, total weight, and count simultaneously may opt for models with multiple screens.

- Battery Operation: Certain counting scales are designed to be portable and battery operated, making them ideal for conducting inventory counts in extensive warehouses or off-site locations.

- Connectivity: Modern counting scales offer the capability to link with computers, printers, and various devices for the purposes of data recording and generating reports. The type of data you depend on and its application will influence your decision on the most effective method of transmitting data from the scale.

- Audible Alerts: This feature offers sound notifications to signify certain actions or conditions, such as the scales reaching a preset weight.

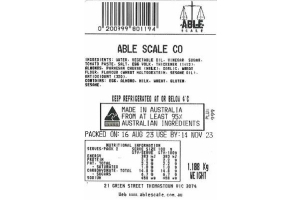

AbleScale’s Collection of Counting Scales for highly Accurate Results

High Resolution Counting Scale - A&D FC-i & FC-Si Series

The A&D FC-i counting scales excel in precisely counting items with small weights. Their design includes the capability to attach a larger secondary scale platform, facilitating the easy counting of both smaller and larger objects.

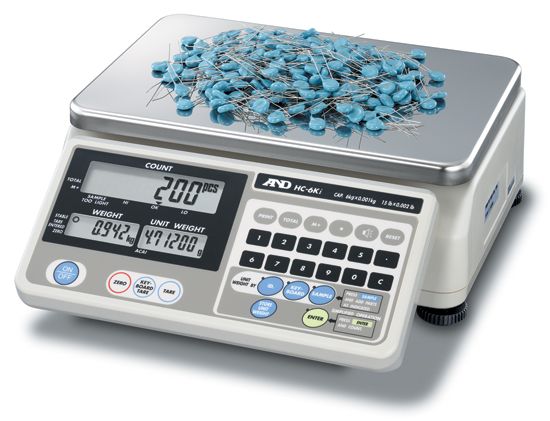

A&D HC-i Series

The A&D HC-i makes small parts counting effortlessly simple, thanks to its user-friendly navigation system which is straightforward and intuitive. Key features include a buzzer function, a detachable display unit, and AC power compatibility (with the option for a rechargeable battery), and more.

Ohaus Ranger RC31P

The Ranger 3000 counting scale is perfect for all your industrial counting requirements. It boasts a portable design, the option to operate via an AC adapter or a rechargeable battery, storage for 30 item data, triple backlit LCD displays for easy viewing, a high internal counting resolution for accuracy, RS232 communication for data transfer, and an optional input for a second scale.

Conclusion

Able Scale stocks a wide range of high quality counting scales, as well as many other products and services that can be found on the Able Scale website. If you’d like to get in touch with us, you can do so via the Able Scale contact us page, or you can email us at info@ablescale.com.au, or call us on 1300 731 360.

Have questions about our products and services?

We are here to help. Please fill in our online enquiry form below, and we will respond to you within the next business day.

Call us Today

Call us Today