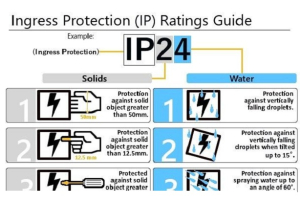

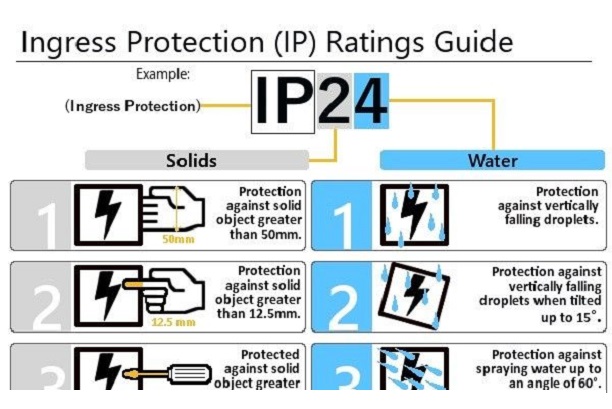

An Ingress Protection rating - most often referred to as an IP rating - is the industry term used to refer to the sophisticated method of assessing the effectiveness of an electrical device's enclosure, so as to prevent it from being infiltrated from water or other foreign particles. Such IP ratings are commonly used for a wide spectrum of consumer goods, encompassing everything from smartphones and wristwatches, to industrial scales.

Whether you use platform scales or measuring scales, water protection is a critical consideration when it comes to the design and continual functionality of any industrial scales that are used for professional or commercial applications. Water, in its many forms, can be a significant threat to the accuracy and durability of scales, potentially leading to malfunctions and inaccuracies. As such, most professionals will seek industrial scales with satisfactory IP ratings. This precaution can help shield your equipment from the unwanted intrusion of dust and moisture, making it particularly beneficial for applications exposed to adverse environmental conditions.

What is an IP Rating, and Why Does it Matter When it Comes to Protecting Your Scales from Water damage?

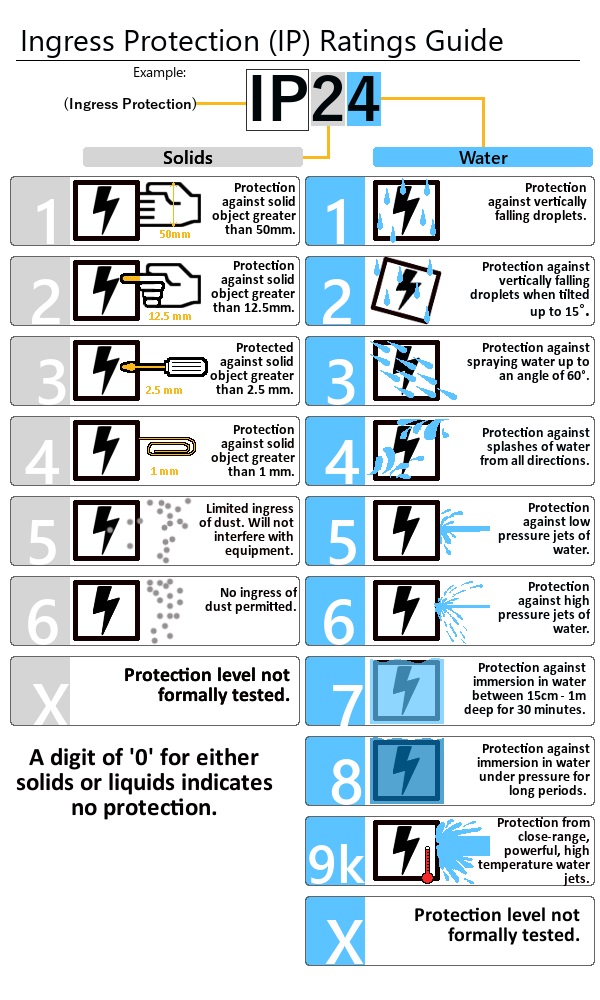

Ingress Protection ratings are organised using categorical codes and are commonly presented in tabulated form. This serves as a metric to gauge an enclosure or casing's capacity to prevent the entry of foreign elements. The categorical code of an IP rating conveys the degree of protection afforded against external intrusions, including sizable objects and contaminants. Such objects and contaminants can vary in size and texture and might include anything from water and dust to a cockroach or a human finger.

In essence, an Ingress Protection rating typically consists of two digits, such as "IP57."

The first digit signifies the level of safeguarding against the ingress of solid objects, while the second digit indicates the resistance to moisture penetration. When combined, these two digits provide precise information about the level of protection offered by a particular case or enclosure.

Products carrying an IP rating must undergo a battery of rigorous tests to assess their performance in diverse conditions. Ultimately, the presence of an IP rating empowers you to make an informed decision regarding the suitability of a product for your specific application, ensuring it meets the required standards of protection against unwanted external factors.

What are Some Common Misconceptions About IP Ratings & Protecting Scales from Water Damage?

Like so many niche corners of an industry, the world of IP ratings can be a bit of a complicated area to navigate; as such, there are some common misconceptions about IP ratings out there that you should definitely be aware of…

IP Ratings Aren’t That Important

Some folks tend to downplay the importance of IP ratings for weighing scales, assuming that scales are not exposed to water or dust in their environment. However, even minimal exposure to moisture or dust over time can adversely affect scale accuracy and performance.

All IP Ratings Are the Same

One of the biggest misconceptions is the assumption that all IP ratings offer the same level of protection. In reality, IP ratings vary, and each digit in the rating indicates a different degree of protection against solids and liquids. Ignoring this distinction can lead to selecting a scale with inadequate protection against water damage.

IP Ratings Guarantee Total Immunity

Some people mistakenly believe that high IP ratings guarantee total immunity from water damage. While a high rating provides substantial protection, it doesn't mean the scale is entirely waterproof. Water exposure beyond the scale's specified limits can still cause damage.

Cleaning = Waterproof

Assuming that a scale can withstand water because it's advertised as "easy to clean" can be a bit of a slippery slope. Cleaning a scale is not the same as immersing it in water, and scales not designed for wet environments may still be vulnerable to water damage.

The Base is Always Protected

There are numerous scales available that feature load cells with IP ratings, but it's important not to be misled. This rating exclusively applies to the electronic components within the load cell, leaving the scale's base and indicator unprotected. In situations where environmental conditions can become messy, this limited protection may not suffice.

IP Ratings Never Change

Over time, the effectiveness of seals and gaskets that provide IP-rated protection can deteriorate. Some users may mistakenly believe that once a scale has a certain rating, it will maintain that level of protection indefinitely. But IP ratings - like any other reputable field of science - is an ever-evolving field, and it’s always changing because it constantly seeks to refine and perfect our knowledge through the lens of new discoveries, technology, and critical evaluation. While it may be a pain to have to keep up with new ratings all the time, we can also be grateful that the new ratings are invariably more accurate than the last.

Tips on How to Maintain and Inspect Your Scales for Signs of Water Damage

Maintaining and inspecting scales for signs of water damage is crucial to ensure their accuracy and longevity. By following the following tips, you can help ensure that your scales remain in good working condition, maintain their accuracy, and minimise the risk of water damage in various environments.

Regular Cleaning: It’s important to clean your scales regularly so as to prevent the buildup of dust, dirt, and moisture. We recommend using a soft, damp cloth and mild cleaning agents, when necessary, but avoid excessive moisture around sensitive components.

Inspect All Seals & Gaskets: Always check the seals and gaskets around the scale's components, including the display, buttons, and load cells. Look for cracks, gaps, or wear that could allow water to enter.

Verify IP Rating: Ensure that your scales have the appropriate IP rating for your specific environment. If they are intended for wet or dusty conditions, they should have a suitable IP rating, such as IP66 or higher.

Avoid Immersion: Never immerse scales in water unless they are explicitly designed for submersion (e.g., IP68 waterproof scales). Even IP-rated scales have limits and exceeding them can lead to water damage.

Avoid High Pressure: Never high pressure wash scales in water unless they are explicitly designed for this (e.g., IP69K). Even IP-rated scales have limits and exceeding them can lead to water damage.

Use Protective Covers: Consider using protective covers or enclosures for your scales in environments with high humidity or the potential for splashes. These covers can provide an extra layer of protection.

Calibration Checks: Periodically calibrate your scales to ensure accuracy, especially if they have been exposed to moisture or temperature variations that could affect calibration.

Monitor for Corrosion: Inspect metal components for signs of corrosion, which can result from prolonged exposure to moisture. Apply anti-corrosion treatments if necessary.

Secure Cable Connections: Ensure that cable connections, especially those near the floor, are well-protected and insulated to prevent water infiltration.

Store Properly: Store scales in a dry and clean environment when not in use. Avoid leaving them exposed to extreme temperature changes or direct sunlight.

Regular Maintenance: Implement a routine maintenance schedule, including professional servicing if needed, to address any issues promptly and prevent potential water damage.

Educate Users: If scales are used by multiple individuals, make sure new users are aware of the scale's IP rating and the proper handling and care required to maintain its protection against water damage.

Document Inspections: Keep records of regular inspections, maintenance activities, and any repairs performed to track the condition of your scales over time.

The Importance of Having a Plan in in Case Your Scales Are Damaged by Water

If your scales are water damaged, it's essential to take immediate action to prevent further damage and ensure their functionality and accuracy. Here are steps to follow:

Safety First: Ensure that the scales are disconnected from power sources to avoid electrical hazards.

Remove from Water Source: If the scales are still in contact with water, carefully remove them from the water source to prevent additional exposure.

Dry Thoroughly: Use absorbent materials like towels or paper towels to gently blot and soak up excess moisture from the scales. Avoid rubbing, as it may push water further into the electronics.

Disassemble (if Safe): If you are familiar with the internal components of the scales, consider disassembling them to allow for better drying. However, only do this if you are comfortable and have experience with electronics.

Use Compressed Air: If available, use compressed air to blow out any remaining moisture from crevices and components. Be gentle to avoid causing further damage.

Rice or Silica Gel: Place the scales and any disassembled parts in a container filled with uncooked rice or silica gel packets. These materials can help absorb residual moisture. Leave them for at least 24-48 hours.

Inspect for Damage: Once thoroughly dried, inspect the scales for signs of damage such as corrosion, loose connections, or physical harm.

Test Functionality: Reassemble the scales if you disassembled them and test their functionality. Ensure that all features, including displays, buttons, and load cells, are working correctly.

Calibration Check: If the scales pass functional tests, perform a calibration check to verify accuracy. If the scales are no longer accurate, they may require professional calibration.

Professional Inspection: If you are uncertain about the scales' condition, or if they exhibit signs of damage that you cannot address, contact a professional scale technician or manufacturer for inspection and potential repairs.

Prevent Future Damage: Implement measures to prevent future water damage, such as using protective covers, relocating the scales to a drier area, or sealing any potential entry points for moisture.

Conclusion

Ingress Protection ratings represent the highest level of safeguarding that an electrical enclosure offers against the infiltration of solid objects and liquids. If you reside in an area where dust and rain can potentially harm your electrical components, it is advisable to consider investing in high-quality equipment that carry adequate IP ratings.

If you’re looking to obtain a top-notch scale with an impressive IP rating, you may wish to consider something akin to the Trade Platform Scale (A&D SC IP68 Platform Scale), a simple yet dependable weigh scale that offers exceptional performance, the option of high resolution for enhanced productivity, and a multi-function option that can perform all your basic platform scale needs. It can run on AC power or battery, and it comes with a counting function, a comparator function, and your choice of floor mount with column or bench mount without column.

Another terrific option is the Ohaus General Purpose Platform Scale (Defender 500). This series of scales has been designed as a general purpose platform scale, making it perfect for shipping, production, packing and general industrial applications. It features 3 colour checkweigh LED and setpoint beeper, painted steel frames, a 25mm backlit display, an integrated carry handle for portability, ABS plastic indicator, multiple weighing units and weighing modes, and a stainless-steel pan.

Alternatively, you may be charmed by the Stainless Steel Platform Scale (Ohaus Valor 4000 IP68 Bench Scale). This is a top-notch solution for businesses that operate in wet environments. This food-safe, IPX8-rated bench scale is crafted with water protection as a priority. It ensures precise measurements even under potentially damaging conditions, safeguarding your devices against the expenses of unnecessary repairs and replacements. Additionally, the Ohaus Valor 4000 is trade-approved up to 15kg, making it a highly reliable and versatile tool for industries of all sizes. Its innovative design and advanced technology offer an unparalleled level of protection against water intrusion, ensuring the longevity of your scales.

At Ablescale, we are dedicated to providing high quality equipment that’s specifically tailored to the needs of private practices, clinics, and hospitals. We stock a vast variety of products, including platform scales and measuring scales (for both retail and industrial use), food equipment, cash registers, weight/labelling scales, custom weighing scales, POS systems, medical scales, laboratory balances, software, and even maintenance/repair services.

You can head over to the Able Scales website to browse our wide range of equipment. If you require assistance in locating specific products or have any inquiries, please don't hesitate to do so directly via the Able Scales Contact Us page, or via our contact email at info@ablescale.com.au. We're here to help!

Have questions about our products and services?

We are here to help. Please fill in our online enquiry form below, and we will respond to you within the next business day.

Call us Today

Call us Today