Industrial Touch Screen POS Terminals

Industries worldwide rely on industrial touch screen terminals to streamline daily operations efficiently. These devices are cleverly engineered to function optimally during the most demanding of environments, providing reliable display solutions. Industrial touch screen terminals are known for their cost-effectiveness and efficiency, tailored for rugged production settings using high-quality industrial components. Unlike traditional PC terminals with their vestigial keys and buttons, touch screens operate via a state of the art software that provides a greater flexibility for packing orders and processing labels. Their ability to endure dust, dirt, moisture, shock, vibration, and extreme temperatures makes them a preferred choice.

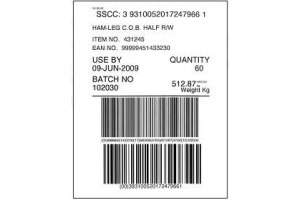

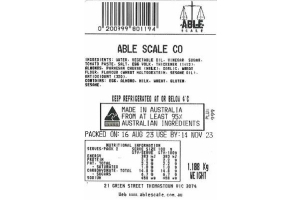

Able Scale offers a range of terminals— such as the Stainless Steel Touch Screen PC - Senor rSPOS — which is housed in a durable enclosure made from stainless steel. With its exceptional durability and powerful software, the Senor rSPOS is perfectly suited for all industrial applications, and pairs well with the Able Scalemate Touch Screen Carton Labeller, a carton labelling device that can be connected to a diverse range of printers and scales suited to a variety of different applications, such as labelling names, addresses, barcodes, batch codes, and whatever else a company requires.

Scroll on to learn how industrial point of sale terminals can revolutionise your industry today…

Why You Should Consider A Touch Screen Carton Labeller & Industrial Touch Screen Terminal

The advantages offered by quality touch screen terminals and carton labellers are manifold. Here are just some of the benefits your company should factor in when considering your purchase:

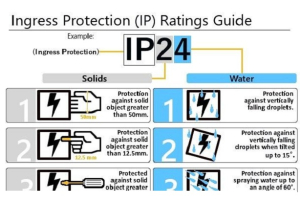

- Dusty Environments: For businesses operating in dusty settings like construction sites or warehouses, an IP66-rated touch screen POS terminals offers vital defence against dust infiltration. This safeguard ensures reliable system operation, mitigating the risk of malfunctions or premature wear due to dust exposure. And carton labellers designed for dusty environments feature sealed enclosures and robust construction, ensuring they can operate reliably without dust infiltration.

- Water Exposure: In establishments prone to water or moisture exposure, such as food processing, an IP66-rated touch screen POS terminals proves advantageous. It withstands accidental spills, cleaning routines, and wet conditions, shielding the system from water damage and sustaining operational integrity.

- Hygiene & Cleaning: Industries requiring stringent cleaning protocols, like food service or healthcare, benefit from an IP66-rated industrial touch screen terminal. It endures intense cleaning procedures without compromising functionality, fostering a clean and hygienic environment. Carton labellers built for industries with strict hygiene protocols, such as food service and healthcare, can be designed to suit. This capability maintains operational integrity and supports a hygienic environment.

- Longevity & Reliability: An industrial touch screen terminal signifies a commitment to durability and dependability. It diminishes the risk of operational interruptions caused by environmental factors, leading to extended longevity, decreased downtime, and enhanced efficiency. Meanwhile, a durable carton labeller reduces downtime and maintenance needs, contributing to extended longevity and enhanced operational efficiency in diverse industrial settings.

- Compliance & Safety: In accordance with industry regulations, an industrial touch screen terminal ensures compliance with safety standards. This certification underscores adherence to guidelines and instils confidence in equipment protection. Carton labellers that meet safety standards ensure compliance with industry regulations, providing assurance of equipment safety and protection in accordance with guidelines.

Industries That Benefit from Industrial Touch Screen POS Terminals

These days, Industrial touch screen POS terminals such as Able Scale Senor rSPOS are commonly found across a wide range of sectors. Here are just a few of the major industries that are currently benefiting from POS systems and carton labelling systems:

- Food Processing: Implementing efficient POS terminals streamlines customer service in bustling sectors like restaurants, bars, and hotels. These systems enable quick transactions, aiding in menu optimization and sales tracking for enhanced business performance.

- Manufacturing: Tailored POS solutions for manufacturing and distribution integrate cash sales seamlessly with inventory and ERP systems, addressing specific industry needs and ensuring accurate record-keeping and inventory management.

- Warehouse & Logistics: Touch screen terminals optimise order fulfilment within warehouse and distribution operations, improving stock visibility, and enhancing connectivity with sales channels, thus ensuring fast and efficient inventory management.

Why Are Industrial Touch Screen Terminals & Carton Labellers Used in the Food Processing Industries?

In the modern world of food processing, carton labellers and industrial touch screen terminals are instrumental in keeping both customers and companies informed and safe. They ensure that all relevant (and in many cases, health preserving) information is printed clearly. Compared to traditional manual production, automatic food processing equipment significantly reduces human involvement, thereby lowering food safety risks and effectively improving overall food safety. In an automated food processing production line, equipment such as barcode scanners, voice modules, PLC controllers, scale modules, and touch display devices form a comprehensive monitoring system for processing and production. As the control centre of this system, a touch display device is important not only for issuing programming instructions but also for data analysis, recording production data, issuing production failure warnings, and uploading data to the cloud.

Food Labelling Laws & Their Importance in Australia

Carton labels are bastions against a lack of information that could be perilous for both customers and companies alike. There are food labelling requirements that must accord with the Australian Consumer Law (ACL) that all labels strictly follow a food standards code. This code demands that label include accurate information that covers:

- Used By & Best Before Dates: The dates on food labels must clearly state how long food can be stored before it deteriorates or becomes unsafe to eat. These dates are labelled in two ways: "use by" and "best before." All food suppliers are required to include either a use by or a best before date on all food packaging.

- Ingredients: Food labels must list ingredients in descending order by their weight contribution to the packaged food. Additionally, the percentages of key ingredients must be listed to allow for comparison with other products.

- Allergens: Certain foods and ingredients can cause severe allergic reactions, so it is crucial to list all allergens, including any and all components, on food labels.

- Country of Origin: Country of origin labels on food packages help consumers make more informed purchasing decisions.

- Nutritional Information: The nutrition information panel must follow a standard format, showing energy, protein, fat, carbohydrates, and sodium per 100g (or 100mL for liquids) serving. It must also list the number or names of any food additives.

- Health Star Rating: The Health Star Rating (HSR) is a voluntary front-of-pack labelling system that evaluates the nutritional profile of packaged foods and assigns a rating from 0.5 to 5 stars, facilitating quick comparison of similar products—the higher the stars, the better the nutritional profile.

- Health Claims: Food laws in Australia require that any health claims on a food label must be supported by scientific evidence.

Using a touch screen Scalemate carton labelling machine in conjunction with a Stainless Steel Touch Screen Senor rSPOS can greatly improve the labelling process. These advanced technologies facilitate precise and efficient label application, minimise human error, and streamline workflows. The touch screen interface supports easy customization and quick adjustments, ensuring all labels comply with regulatory standards and are accurately traceable throughout the supply chain.

While this may seem like a lot to take on for fledgling factory workers, quality carton labelling machines and intuitive POS systems like the Senor rSPOS make labelling a breeze.

The Benefits of Using Industrial Touch Screen Terminals for Your Business

- Speed & Accuracy: A streamlined checkout procedure coupled with instantaneous inventory management will provide an improved precision to your overall operation.

- Time Saving: Modern touch screen terminals boast high user-friendliness, ensuring quick adaptation for both your staff and your customers. An intuitive POS terminal expedites checkout, particularly during peak hours, bolstering sales. Additionally, streamlined operations enable better financial tracking through real-time reports, leading to cost savings.

- Customised Workflows: Your business can now benefit from streamlined operations and enhanced productivity. Custom workflows can be designed to meet the unique needs of the business, improving data accuracy, speeding up processes, and providing real-time insights. This ultimately leads to increased efficiency, reduced training time for employees, and better overall performance.

- Sales Reports: When running a profitable business, making informed decisions with precise data is an imperative. Within a POS system, all analytics are accessible at the drop of a hat.

Able Scale’s Solution for your Industrial Labelling Requirements

The Stainless Steel Touch Screen PC - Senor rSPOS features a stainless steel housing and an IP66 rating. Boasting waterproof circular connectors, this stainless steel rSPOS terminal is tailor-made for industrial settings, and it can let you effortlessly connect to accessories such as scales, printers, or scanners. Key features encompass a stainless steel SUS304 chassis and an IP66 water-resistant rating.

You may also wish to consider the Able Scalemate Touch Screen Carton Labeller, which is perfect for small to mid-sized operations that require carton labelling. It can offer any business versatility by offering a seamless connectivity to a range of printers and scales. Key features include an industrial-grade panel PC with touch screen display, a fanless design for quiet operation, a fast processor for reliable performance, and multiple I/O ports facilitating efficient communication across different devices.

Conclusion

You can check out Able Scale’s selection of industrial POS terminals here, or browse our many other products and services here. Got a question? Don’t be afraid to get in touch with us directly via the Able Scale contact us page.

Have questions about our products and services?

We are here to help. Please fill in our online enquiry form below, and we will respond to you within the next business day.

Call us Today

Call us Today